Shipbuilding

4.O INDUSTRIAL Ai

The Problem

Modern shipbuilding faces increasing complexity, with fragmented data sets, rising costs, and strict regulatory compliance requirements. Engineers struggle with a lack of unified visibility across design, production, and compliance, which leads to inefficiencies, project delays, and increased risks. Additionally, securing sensitive data and ensuring regulatory compliance, especially with evolving cyber threats, presents significant challenges in deploying and managing digital tools effectively.

To overcome these barriers, a solution is needed that integrates disparate data sources into a single, cohesive view, while providing built-in, PROTECTED level cyber security, ensuring compliance and protecting critical shipbuilding processes.

4.O INDUSTRIAL Ai

The Solution

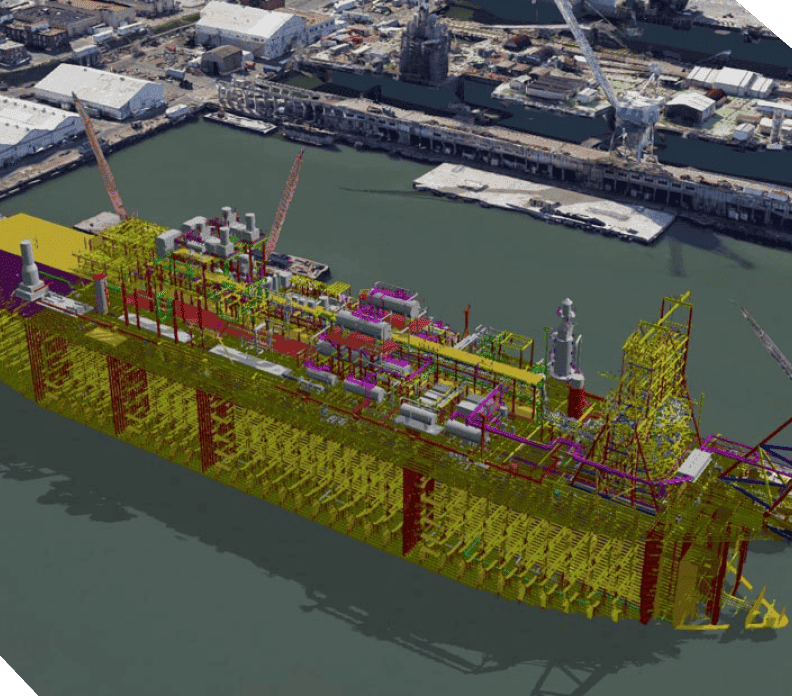

Introducing our advanced Digital Twin solution, powered by a comprehensive data ontology that seamlessly integrates diverse data sets into a unified, “single pane of glass” view. This enables shipbuilding engineers to streamline project management, improve decision-making, and ensure end-to-end visibility across design, production, and compliance.

Coupled with our secure cloud platform offering out-of-the-box PROTECTED level cyber security, the Digital Twin can be deployed with confidence, meeting stringent regulatory standards. This integration accelerates time-to-market, optimizes costs, and mitigates risks, all while ensuring that modern shipbuilding stays efficient, compliant, and future-ready.

Ultimately the objective of using a Digital Twin as a through-life management tool for the development and operation of the vessel is to achieve the following:

- Improved efficiency in both construction and operation

- Seamless data and record-keeping from inception to end-of-life of the asset

- Improved health and safety outcomes

- Reduced downtime through unforeseen component failure

- Enhanced maintenance planning and delivery

REQUEST A DEMO

Let’s Talk

Have some questions that weren’t answered on the website, let us know.